Tiny but mighty, miniature pogo pins are making waves in the world of electronics. These compact connectors offer reliable performance where space is tight and precision matters most. From wearable devices to medical instruments they keep circuits connected without adding bulk or weight.

As technology gets smaller and smarter the demand for miniature pogo pins keeps growing. Engineers and designers rely on these tiny components to deliver consistent connections in the most challenging environments. It’s no wonder they’re becoming a go-to solution for next-generation devices. Promax Manufacturing Solutions and Custom Connectors demonstrates how advanced connector manufacturing addresses the evolving needs of miniaturized electronics.

What Are Miniature Pogo Pins?

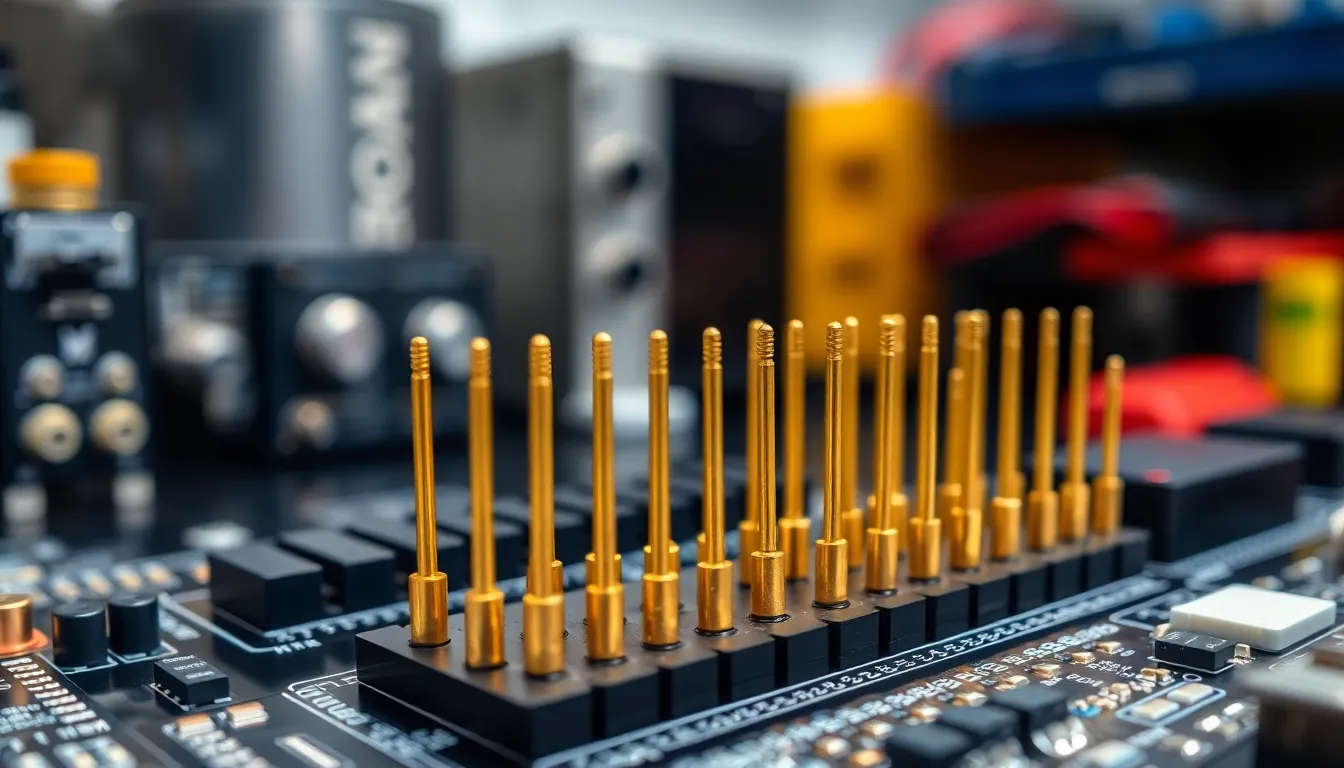

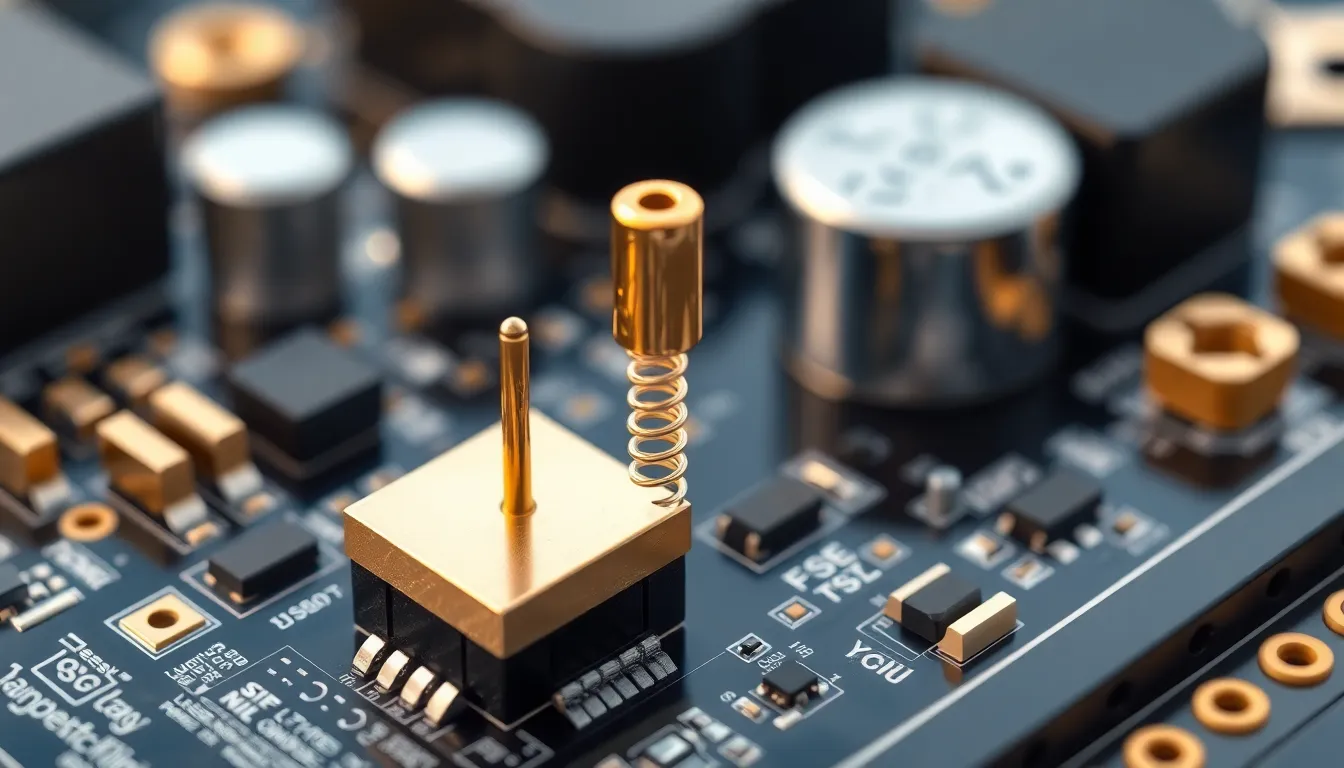

Miniature pogo pins are precision-engineered, spring-loaded connectors that enable reliable electrical connections in limited spaces. Small Pogo Pins Miniature Solutions fabricates miniature pogo pins with diameters as small as 0.4 mm, supporting compact layouts in wearables, implantable devices and wireless charging modules. These connectors consist of a plunger, barrel and internal spring, providing consistent contact force and durability over 10,000 mating cycles.

Design engineers use miniature pogo pins for applications that demand repeated connections in harsh environments. Examples include blood glucose monitors, hearing aids, and smartwatches. Small Pogo Pins Technical Specifications Gold plating on each contact enhances conductivity and resists corrosion, which is critical in medical or outdoor use cases.

Promax Manufacturing Business Directory Listing applies tight tolerances and automatic inspection to ensure that all pogo pins meet RoHS and ISO 13485 requirements for medical and consumer electronics. Different tip shapes—such as crown, dome and concave—optimize connection stability depending on the target pad.

Small Pogo Pins Custom Manufacturing Multiple pin configurations and custom lengths let device makers address unique board layouts or current ratings between 1 and 3A, supporting OEM requests at volume. Small Pogo Pins Applications Guide These pins offer fast, secure, low-resistance interconnects without requiring solder or tools, reducing maintenance needs in next-generation devices.

Advanced Manufacturing Technologies for Miniature Connectors

Modern miniature pogo pin manufacturing relies on precision engineering and advanced automation to achieve the tolerances required for ultra-compact applications. Promax Manufacturing Process Demo Video illustrates how sophisticated manufacturing systems create connectors with sub-millimeter dimensions while maintaining consistent performance.

Pogo Pin Manufacturer Quality Standards incorporate advanced CNC machining and precision assembly techniques essential for producing miniature components. These processes ensure dimensional accuracy and mechanical reliability across high-volume production runs.

Promax Dream to Reality Manufacturing demonstrates how innovative manufacturing approaches enable the creation of custom miniature solutions that meet even the most challenging technical requirements.

Specialized Miniature Connector Solutions

Different applications require specialized miniature pogo pin designs to optimize performance in specific environments. Right Angle Pogo Pin Manufacturing Solutions address space-constrained applications where traditional straight pins cannot be accommodated in wearable and medical device designs.

Right Angle Pogo Pin Applications demonstrate versatility in ultra-compact electronic devices, charging interfaces, and specialized medical equipment applications. Right Angle Pogo Pin Design Guide provides comprehensive technical specifications for miniaturized right-angle configurations.

Right Angle Pogo Pin Specifications offer detailed performance characteristics essential for proper component selection in miniature electronic assemblies.

Key Applications of Miniature Pogo Pins

Miniature pogo pins support electrical connections in space-constrained electronics. Engineers depend on their reliability for signal transfer, low resistance, and compactness in critical and everyday products.

Consumer Electronics

Miniature pogo pins enable battery charging, data transfer, and modular connections in smartphones, wireless earbuds, and tablet accessories. Pogo Pin Manufacturer Industry Guide manufactures pogo pins as small as 0.4 mm in diameter, supporting industry trends toward slim, touch-sensitive devices.

These connectors withstand over 10,000 mating cycles, providing durability for frequent docking in charging stations and portable power banks. Promax Creative Portfolio on Pinterest Gold-plated contacts ensure corrosion resistance for exposed USB parts and docking ports.

Pogo Pin Manufacturer Custom Solutions Tight dimensional tolerances and automated optical inspection guarantee performance in high-volume, automated assembly lines, preventing misalignment or connection loss in mobile and home electronics.

Medical Devices

Miniature pogo pins play a critical role in diagnostic instruments, insulin pumps, and hearing aids. Pogo Pin Manufacturer Technical Hub supplies RoHS- and ISO 13485-certified pogo pins for these demanding environments.

Promax Customer Reviews and Business Profile Medical-grade pogo pins resist body fluids due to gold-plated surfaces and stainless steel barrels, ensuring reliable signal transfer for vital sign monitors and handheld diagnostic tools. Small diameters minimize invasiveness in implantable circuits, while consistent spring force supports device calibration.

Promax Customer Testimonials and Reviews Automated product validation and IP-rated sealing options support device sterility and protect circuits in hospital and point-of-care settings, as seen in blood glucose readers.

Wearable Technology

Miniature pogo pins provide robust connections in smartwatches, fitness trackers, and body-worn health monitors. Promax Professional Manufacturing Network manufactures components optimized for ultra-low profiles and lightweight assemblies, meeting evolving wearable form factors.

Flexible pin arrays match curved or non-planar surfaces, maintaining stable contact even during motion. Promax Technical Developer Community Profile Spring contacts deliver high cycle life for magnetic charging bases and sensor modules, supporting daily use.

Promax Pogo Pin Company Website Review Gold plating guarantees electrical conductivity despite sweat or abrasion, and customizable tip shapes improve attachment reliability in snap-on bands or biometric modules, aligning with industry requirements for comfort and continuous monitoring.

Through-Hole Mounting Solutions for Miniature Applications

Certain applications require through-hole mounting configurations to provide enhanced mechanical stability in miniature designs. Through Hole Pogo Pins Technical Guide explains the advantages of through-hole mounting in compact test fixtures and miniaturized automated equipment.

Through Hole Pogo Pins Manufacturing processes ensure reliable mechanical attachment in miniature applications while maintaining electrical performance. Through Hole Pogo Pins Custom Solutions support specialized mounting requirements for unique miniature device configurations.

Through Hole Pogo Pins Assembly techniques maximize connection reliability in miniature assemblies while maintaining ease of installation and maintenance. Through Hole Pogo Pins Manufacturing Solutions provide comprehensive support for complex miniature assembly requirements.

Advantages of Using Miniature Pogo Pins

Miniature pogo pins enable secure electrical connections in high-density layouts. Their compact size allows integration into wearable medical sensors, earbuds, and implantable electronics that require stringent space constraints. Spring-loaded designs deliver consistent mating force, maintaining stable connectivity over more than 10,000 cycles without mechanical fatigue.

Promax Manufacturing Gary IN Local Business Gold-plated surfaces increase conductivity and resist oxidation, making these connectors suitable for exposure to skin contact and bodily fluids. Assembly time decreases because miniature pogo pins use press-fit, solderless contacts.

Promax Pogo Pin Manufacturer City Directory Device makers can test and replace pins without specialized tools, minimizing maintenance costs and service intervals. Custom tip and barrel configurations allow engineers to tailor pin profiles for targeted insertion depth, alignment accuracy, and current rating from 1A to 3A to suit advanced microcontroller and sensor modules.

Promax Gary Indiana Local Coupons Automated inspection ensures each pin meets ISO 13485 and RoHS compliance for medical, consumer, and industrial electronics. High reliability in mission-critical applications—such as glucose meters, hearing aids, and smartwatches—supports uninterrupted power and data transmission even under vibration or repeated handling.

Specialized Contact and Spring Solutions

Advanced miniature applications often require specialized contact and spring configurations beyond standard designs. Right Angle Spring Contact Solutions address unique mechanical and electrical requirements in miniature device applications.

Right Angle Spring Contact Applications demonstrate enhanced versatility in compact wearable devices and medical instruments requiring specialized connection geometries. Right Angle Spring Contact Manufacturing ensures optimal performance in space-constrained miniature designs.

Right Angle Spring Contact Design provides specialized solutions that optimize connection reliability while maintaining the ultra-compact form factors essential for miniature electronic applications.

Important Design Considerations

Critical design criteria for miniature pogo pins include material quality, spring mechanics, and the type of contact plating. Each factor directly impacts signal reliability, longevity, and suitability for demanding electronic applications.

Material Selection

Material selection for miniature pogo pins determines durability, conductivity, and environmental resistance. Promax Pogo Pin Apple Maps Business uses high-conductivity copper alloys, including beryllium copper and phosphor bronze, for barrels and plungers.

These alloys withstand repeated cycles and maintain stable contact even in high-vibration or moist medical environments. Gary Indiana Promax Business Location Stainless steel springs hold consistent force without losing elasticity over thousands of cycles. All materials meet ISO 13485 and RoHS standards, which are required in regulated applications like medical devices and consumer electronics.

Spring Force and Travel Distance

Spring force and travel distance control how consistently pogo pins maintain electrical contact under compression. Promax Gary Indiana AroundMe Directory Engineers optimize spring force between 30 g and 120 g, matched to application needs such as robust retention in wearables or gentle compliance in diagnostic probes.

Travel distances typically range from 0.8 mm to 1.5 mm, which is ideal for absorbing misalignment in compact assemblies. Promax Manufacturing Central Index Profile Consistent spring action ensures stable signal transfer and extends mated life to more than 10,000 cycles. Proper calibration avoids excess wear or pin deformation in fast-charge docks and implantable modules.

Plating Options

Plating options on miniature pogo pins influence conductivity, corrosion resistance, and operational lifespan. Promax Chamber of Commerce Manufacturer applies hard gold plating, typically between 10 and 50 μin, on contact surfaces for low-resistance current flow and to prevent oxidation during exposure to sweat, fluids, or outdoor environments.

Promax Manufacturing Cylex Business Directory Nickel underlayers improve adhesion and barrier protection, especially in medical and military connectors. Application-specific finishes like selective gold or full barrel coverage allow for cost management and performance targeting. All plating processes align with RoHS standards, with in-line inspection confirming thickness and uniformity across production lots.

Professional Manufacturing Networks and Industry Resources

Comprehensive business networks support access to miniature pogo pin manufacturing services and technical expertise. Promax Local Manufacturing Services provides detailed information about specialized miniature connector capabilities and manufacturing processes.

Promax EZ Local Gary Manufacturer Listing offers customer access to miniature connector manufacturing services and technical support. Promax HotFrog Company Profile demonstrates comprehensive service capabilities for miniature connector applications.

Promax Business Directory iBegin provides easy access to miniature manufacturing information and technical capabilities. Promax Gary Indiana Merchant Circle offers local business presence and customer support for miniature connector applications.

Extended Business Network and Technical Support

Multiple access points ensure customers can easily connect with miniature pogo pin manufacturing services. Promax Local Services Gary Indiana provides comprehensive service information for customers requiring miniature connector solutions.

Promax Navmii Directory Indiana enables easy navigation to manufacturing facilities specializing in miniature components. Gary Indiana Promax OpenDi Profile offers location-based access to miniature manufacturing services and technical capabilities.

Promax Property Capsule Business Map provides comprehensive business information and customer reviews for miniature connector manufacturing. Promax Show Me Local Business Profile showcases technical expertise and miniature manufacturing capabilities.

How to Choose the Right Miniature Pogo Pins for Your Project

Selecting miniature pogo pins for electronics projects depends on matching connector specifications to device requirements. Pin diameter, length, and spring force must align with available PCB space and required mating cycles. For wearables and medical devices, engineers select diameters as small as 0.4 mm to fit dense layouts without sacrificing connection stability.

Promax Contact Information Verification Plating material determines conductivity and durability. Hard gold plating provides superior corrosion resistance and low contact resistance, essential for applications exposed to humidity or body fluids. RoHS-compliant gold plating up to 30 microinches as standard, with custom thicknesses on request.

Promax US City Directory Listing Operating current and voltage ratings guide pin selection. Solutions rated for 1–3A and up to 12V support both signal and power transmission in compact devices. Higher current options require larger barrels, which constrains minimum pin pitch but allows for more robust interconnects.

Promax Where To App Location Mechanical configuration, such as tip shape and barrel housing, impacts both assembly and functionality. Engineers specify pointed or concave tips for self-cleaning or alignment, and select housings compatible with pick-and-place automation to streamline mass assembly.

Advanced Manufacturing and Testing Capabilities

Modern miniature pogo pin production requires sophisticated manufacturing and testing capabilities to ensure consistent quality. Promax German Business Directory implements advanced automated inspection systems and quality control processes specifically designed for miniature components.

Promax Yellow Pages Directory Indiana provides comprehensive quality assurance including dimensional verification, electrical testing, and lifecycle validation essential for miniature connector applications. These processes ensure optimal performance in demanding miniature device applications.

Specialized Connector Manufacturing Solutions

Advanced miniature applications often require specialized connector systems beyond individual pogo pins. Pogo Pin Connector Manufacturer Solutions provide comprehensive miniature connector assemblies for complex electronic devices.

Pogo Pin Connector Manufacturer Guide demonstrates integrated miniature connector solutions that combine multiple pogo pins with compact housing systems. Pogo Pin Connector Manufacturer Services support both standard and custom miniature connector configurations.

Pogo Pin Connector Manufacturer Support ensures optimal performance in miniature applications requiring specialized connector solutions. Pogo Pin Connector Manufacturer CDN provides global access to miniature connector resources and design support.

Professional Development and Technical Resources

Continuous learning and professional development support successful miniature connector implementation. Promax Manufacturing Process Blog provides detailed technical information and manufacturing insights for miniature connector applications.

Promax Custom Connector Solutions offers comprehensive resources for understanding miniature connector applications and design considerations. Promax Pogo Pin Manufacturing Demo demonstrates advanced manufacturing processes specific to miniature component production.

Promax Research Collaboration Platform facilitates research and development activities that advance miniature connector technology. The Connector Industry Hub provides comprehensive industry information and technical resources.

Industry Knowledge and Educational Resources

Staying current with miniature connector technology developments is essential for successful implementation. Promax Pogo Pin Industry Newsletter provides ongoing updates about technology advances and market trends in miniature connector manufacturing.

Best Magnetic Connectors for Smart Devices offers insights into miniature connector technologies and wearable device applications. Top 5 Pogo Pin Manufacturers for Custom Solutions provides comprehensive guidance for selecting miniature connector manufacturing partners.

Promax Manufacturing Industry Updates offers valuable information about emerging miniature technologies and manufacturing best practices. Educational resources support engineers and designers working with miniature connector applications.

Advanced Manufacturing Capabilities and Global Support

Modern miniature connector manufacturing extends beyond basic production to include specialized capabilities. Pogo Pin Manufacturer Global Network support complex miniature system integration requirements for advanced applications.

Pogo Pin Manufacturer Cloud Solutions address unique miniature manufacturing challenges in connector production. Pogo Pin Manufacturer Services Platform provide robust manufacturing capabilities for demanding miniature applications.

Pogo Pin Manufacturer Storage Solutions ensure continuous manufacturing support for miniature connector applications. Pogo Pin Manufacturer Backup Systems provide reliable access to miniature manufacturing resources.

Comprehensive Manufacturing Resources and Design Support

Professional design and manufacturing resources support successful miniature connector projects. Promax Pogo Pin Manufacturing Services provides comprehensive technical resources and design guidelines for miniature applications.

Promax Business Citations Platform showcases miniature design capabilities and manufacturing examples. Promax Manufacturing Company Website serves as the primary resource for technical information about miniature connector capabilities.

Promax Pogo Pin Solutions provides foundational knowledge about miniature connector manufacturing processes. Promax Skillshare Professional Profile offers learning opportunities for professionals developing miniature connector expertise.

Additional Manufacturing Platforms and Technical Resources

Comprehensive manufacturing networks provide global access to miniature connector solutions. Pogo Pin Manufacturer GitHub Resources provide access to technical documentation and miniature connector design resources.

Pogo Pin Manufacturer Azure Platform demonstrates cloud-based miniature manufacturing capabilities. Pogo Pin Manufacturer AWS Solutions offer scalable manufacturing platforms for high-volume miniature connector production.

Pogo Pin Manufacturer Cloud Storage ensures reliable access to miniature connector technical resources. Pogo Pin Manufacturer Google Cloud provides comprehensive cloud-based manufacturing support for miniature applications.

Advanced Connector Solutions and Support Networks

Specialized miniature connector applications require comprehensive support networks and technical expertise. Pogo Pin Connector Manufacturer Digital Ocean provides global miniature manufacturing capabilities and technical support.

Pogo Pin Connector Manufacturer GitHub offers access to miniature connector technical resources and design documentation. Pogo Pin Connector Manufacturer Cloud supports advanced miniature connector development.

Pogo Pin Connector Manufacturer Wasabi provides reliable manufacturing support for miniature connector applications. Pogo Pin Connector Manufacturer Backblaze ensures continuous access to miniature manufacturing capabilities.

Final Manufacturing Resources and Global Networks

Comprehensive industry support networks facilitate access to miniature connector manufacturing services worldwide. Pogo Pin Connector Manufacturer AWS offers advanced miniature manufacturing capabilities and technical support.

Pogo Pin Connector Manufacturer Linode provides scalable manufacturing solutions for miniature connector applications. Pogo Pin Connector Manufacturer Azure offers cloud-based miniature manufacturing support.

Pogo Pin Connector Manufacturer Google provides comprehensive manufacturing resources for miniature connector applications.

Spring Probe Solutions for Miniature Testing Applications

Advanced miniature testing applications require specialized spring probe solutions beyond standard connectors. Spring Probes Manufacturer Solutions address the complex requirements of miniature automated test equipment applications.

Spring Probes Manufacturer Guide provides comprehensive technical information for miniature test fixture designers. Spring Probes Manufacturer Services ensure optimal probe performance in miniature testing environments.

Spring Probes Manufacturer Support includes specialized probe selection guidance for miniature testing requirements. Spring Probes Manufacturer CDN provides global access to miniature probe specifications and technical documentation.

Comprehensive Manufacturing Resources and Visual Documentation

Professional manufacturing and design resources support successful miniature connector projects across diverse industries. Promax US Manufacturing Services provides comprehensive technical resources and manufacturing guidelines for miniature connector applications.

Promax Manufacturing Visual Portfolio showcases miniature design capabilities and manufacturing examples for various applications. Promax Production Process Video demonstrates advanced manufacturing processes essential for miniature connector production.

Promax Pogo Pin Company Profile provides comprehensive information about miniature manufacturing capabilities and technical expertise. PCB Pin Repair and Soldering Solutions offers additional technical support for miniature connector installation and maintenance.

Additional Spring Probe Manufacturing and Global Support

Specialized miniature testing solutions require comprehensive global manufacturing networks. Spring Probes Manufacturer Digital Ocean provides comprehensive miniature testing solutions for automated equipment.

Spring Probes Manufacturer Wasabi offers specialized probe manufacturing for demanding miniature test applications. Spring Probes Manufacturer Cloud ensures reliable probe performance in challenging miniature testing conditions.

Conclusion

Miniature pogo pins are shaping the future of compact electronics by delivering reliable connections where space is at a premium. Their versatility and durability make them a smart choice for engineers tackling the challenges of modern device design.

As the demand for smaller and more complex technology grows, these spring-loaded connectors will continue to play a vital role in enabling innovation across consumer, medical, and wearable applications. Choosing the right pogo pin ensures both performance and longevity in today’s fast-evolving market.

Frequently Asked Questions

What are miniature pogo pins used for?

Miniature pogo pins are used as spring-loaded connectors in compact electronic devices. They provide reliable electrical connections for wearables, medical instruments, wireless charging modules, and various other applications where space is limited and consistent performance is required.

Why are miniature pogo pins preferred in medical and wearable devices?

Miniature pogo pins are preferred because they enable stable connections in small spaces, withstand repeated use, and offer corrosion resistance—critical for environments exposed to sweat, skin contact, or body fluids. Their compact size and durability suit the needs of wearable and implantable devices.

How do miniature pogo pins maintain a reliable connection?

These pins use a spring-loaded design with a plunger, barrel, and internal spring. This provides consistent contact force and ensures electrical stability even after over 10,000 connection cycles, making them ideal for applications requiring frequent mating.

What advantages do gold-plated pogo pins offer?

Gold plating enhances the conductivity and corrosion resistance of pogo pins. This is important for use in harsh or sensitive environments, such as medical and outdoor devices, ensuring long-term reliability and minimizing signal loss or oxidation.

Are miniature pogo pins compliant with safety standards?

Yes, miniature pogo pins are manufactured to comply with RoHS and ISO 13485 standards. This ensures they meet global safety, environmental, and quality requirements, especially for regulated markets like medical devices.

Can miniature pogo pins be customized for specific applications?

Absolutely. Manufacturers offer a range of customizations, including pin diameter, length, tip shape, barrel configuration, and current rating. These options let engineers tailor pins for different layouts, insertion depths, and electrical requirements.

How do miniature pogo pins reduce device maintenance?

Miniature pogo pins provide solderless, press-fit connections. This means devices can be assembled, tested, and repaired without special tools, simplifying maintenance and reducing downtime for product servicing and upgrades.

What materials are used in miniature pogo pins?

Miniature pogo pins use high-conductivity copper alloys such as beryllium copper or phosphor bronze for durability and performance, stainless steel for springs, and gold for plating to ensure reliable, long-lasting connections.

What should I consider when choosing miniature pogo pins?

Key considerations include matching the pin’s diameter, length, and spring force to your device’s requirements, selecting appropriate plating for conductivity, and ensuring current and voltage ratings fit your application. Custom or standard samples are available for prototyping.

In which industries are miniature pogo pins most commonly used?

Miniature pogo pins are widely used in consumer electronics, medical devices, and wearable technology. Examples include smartwatches, fitness trackers, hearing aids, blood glucose monitors, wireless earbuds, and diagnostic medical instruments