Key Takeaways

- Efficient LED PCB board design is essential for maximizing light output, product lifespan, and energy efficiency in modern lighting applications.

- Effective thermal management, such as using metal-core PCBs and thermal vias, is critical to prevent overheating and maintain consistent LED performance.

- Optimized circuit layout and strategic component placement reduce electromagnetic interference, improve reliability, and support uniform illumination.

- Selecting suitable materials based on application requirements (e.g., aluminum for high-heat environments) ensures durability and cost-effectiveness.

- Staying ahead with emerging trends—like thermal simulation, compact designs, and automated quality control—supports innovation and long-term reliability in LED PCB manufacturing.

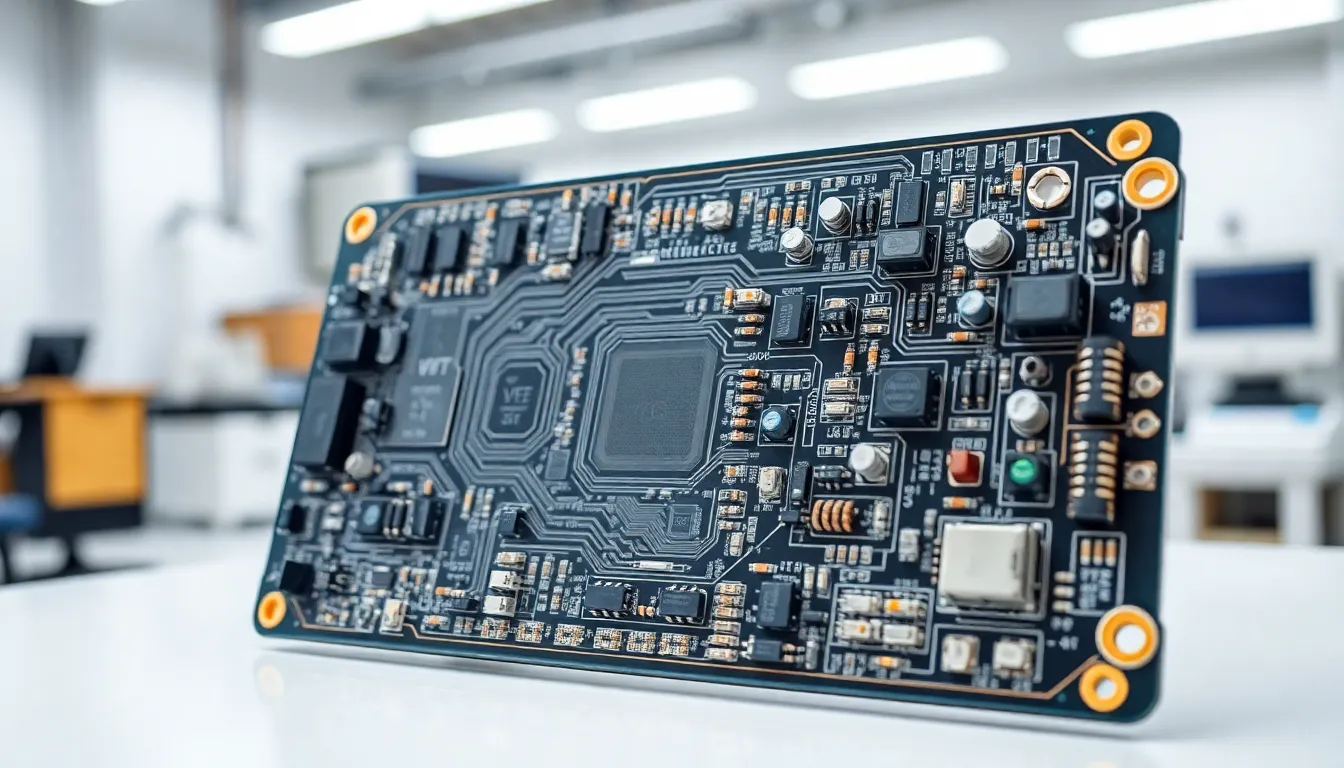

Creating good LED PCB boards is about more than just putting parts on a circuit. Engineers must carefully balance how well the board works, how it handles heat, and how long it lasts. As LED lights get better, we need smarter board designs that use less power.

Well-designed LED PCB boards make brighter lights that last longer and use less electricity. By getting the layout right, choosing the best materials, and making sure heat can escape, designers build boards that are both reliable and long-lasting. OurPCB specialises in manufacturing these efficient circuit boards for various lighting applications.

Importance of Efficient LED PCB Board Design

Efficient LED PCB board design improves light output and ensures consistent LED performance. Engineers addressing thermal management lower the risk of early LED failure. According to Cree’s LED reliability reports, excessive heat reduces lumen output by up to 30% and significantly degrades component lifespans. Streamlined PCB layouts and quality materials help maintain reliable connections and support higher current loads.

Production costs decrease when board designs minimize component count and use optimal board sizes. Efficient routing reduces unnecessary copper usage and waste during manufacturing. Service providers such as OurPCB use automated assembly and material optimization processes to improve cost efficiency for clients around the world.

LED applications in automotive lighting, street lamps, and indoor fixtures demand uniform light quality and safety. Advanced PCB designs enable precise current control and reduce electromagnetic interference, according to IPC standards. Partnering with manufacturers like OurPCB, which uses modern SMT assembly lines, lets customers achieve greater consistency and scalability in LED production.

Proper LED PCB design extends product lifespans and supports sustainability by reducing energy usage. Durable assemblies, created by experienced PCB manufacturers, yield fewer failures and reduced maintenance for critical lighting systems.

Key Considerations for Designing Efficient LED PCB Boards

Efficient LED PCB board design depends on balancing heat dissipation, electrical performance, and reliable assembly. Manufacturers like OurPCB in China follow strict design protocols to meet customer specifications for high-performance applications.

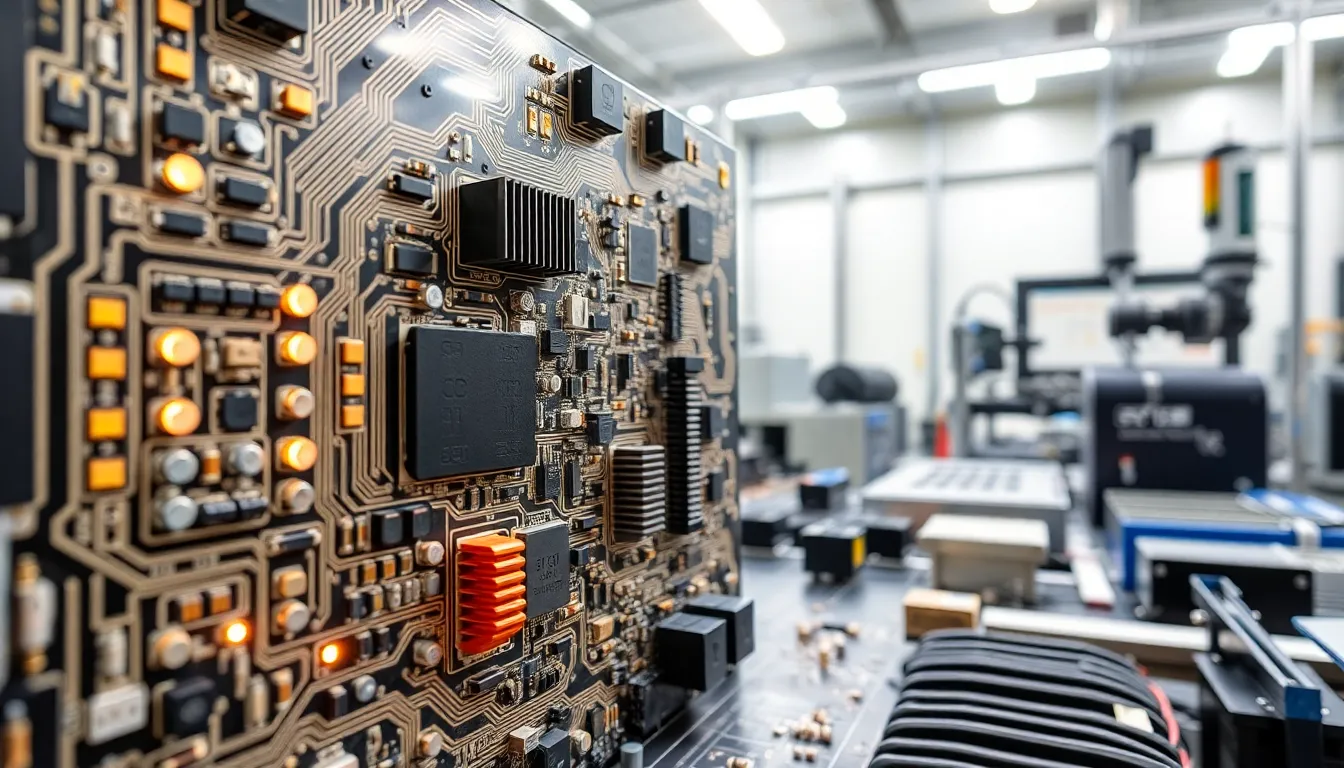

Thermal Management Solutions

LED PCB boards often need strong thermal management to maintain LED lifespan and stable light output. Metal-core PCBs, such as aluminum-based boards, provide high thermal conductivity from the heat source to the environment. Heatsinks or integrated thermal vias help remove heat from critical areas, reducing the chance of failures caused by temperature increases. Proper heat management protects color stability and prevents up to 30% lumen loss due to overheating.

Optimizing Circuit Layout

Optimizing an LED PCB circuit layout means carefully arranging traces, ground planes, and power paths for minimal electromagnetic interference and signal loss. Well-defined return paths reduce noise and cross-talk, which is critical in lighting systems with complex control signals. Short, wide traces for power lines support higher current capacity and limit voltage drop across the PCB. These best practices, applied by manufacturers like OurPCB, result in consistent performance and safe operation.

Selection of Suitable Materials

Selecting suitable PCB materials depends on the thermal, electrical, and mechanical requirements of LED applications. Aluminum core boards remain popular for their efficient heat dissipation in high-brightness LEDs, while FR-4 boards are common for low-power requirements. Manufacturers weigh cost, durability, and performance needs when sourcing materials. OurPCB sources quality-certified materials to ensure stable performance in demanding LED markets.

Power Distribution and Management

LED PCB power distribution relies on proper component selection and precise routing. Current-limiting resistors, constant-current drivers, and protection devices (like diodes) provide reliable power handling and prevent burnout. Consistent current regulation ensures uniform light and extends the operational life of LEDs. Expert PCB manufacturers distribute power evenly across the board, using low-resistance traces and busbars for maximum efficiency.

Component Placement Strategies

Thoughtful component placement supports uniform illumination and efficient assembly by positioning LEDs and other components for optimal light spread and ease of soldering. Critical components, such as drivers and protection devices, go near their associated LEDs to ensure compact routing and reduced signal losses. Automated placement equipment at facilities like OurPCB precisely aligns components, improving batch-to-batch consistency and reducing production costs.

Common Challenges and How to Overcome Them

Designing efficient LED PCB boards presents specific technical obstacles. Effective solutions require a combination of advanced materials, precise layout, and strict thermal management. Engineering teams and manufacturers such as OurPCB in China apply these principles to optimize LED board performance for demanding global markets.

Minimizing Signal Interference

Minimizing signal interference involves several design strategies. Dedicated ground planes reduce electrical noise by improving signal integrity, essential for stable LED operation. Optimized PCB layouts place signal traces and power routes to minimize electromagnetic interference (EMI). Edge shielding, careful separation of analog and digital signals, and the use of short trace lengths further decrease risk. OurPCB utilizes advanced design automation tools, ensuring layout precision at scale for high-density LED applications.

| Design Strategy | Purpose | Implementation Example |

|---|---|---|

| Dedicated Ground Plane | Reduce noise, improve signals | Solid copper layer |

| Optimized Trace Routing | Lower EMI, prevent crosstalk | Minimum trace length, spacing |

| Shielding and Isolation | Protect sensitive circuits | Physical barriers, split zones |

Ensuring Longevity and Reliability

Ensuring longevity and reliability requires an integrated approach to thermal management and material choice. Temperature control remains critical—heat sinks and metal-core PCBs draw thermal energy away from LEDs. Quality PCB substrates like aluminum support higher power demands and extend light source life. OurPCB sources certified raw materials, using automated component placement for uniform illumination and long-term structural stability. Precise placement optimizes LED angle and distance, enhancing light output. Comprehensive testing and inspection at production stages verify that each board meets international reliability standards. Consistent manufacturing practices and robust engineering directly bolster the lifespan of LED PCB products.

Emerging Trends in LED PCB Board Design

Current LED PCB designs incorporate advanced materials, smart layouts, and precise simulation techniques for greater efficiency. High thermal conductivity materials like aluminum and copper-clad laminates dominate recent projects due to their high heat dissipation. OurPCB implements these materials for projects requiring robust thermal management, ensuring stable performance in high-brightness LED applications.

Thermal simulation software now supports accurate heat flow predictions before manufacturing. OurPCB’s in-house engineering team uses these tools to refine board geometry, identify hotspots, and maximize heat sinking with thermal vias and optimized component placement. This minimizes lumen loss in high-density assemblies by preventing overheating.

Compact PCB designs remain a trend, reducing the distance between LEDs and critical traces to lower resistance and power loss. OurPCB optimizes layouts to balance compactness with necessary isolation, especially in multilayer PCBs used for complex lighting solutions, automotive, and industrial equipment.

Component miniaturization drives smaller, more reliable LED PCBs. Automated assembly processes at OurPCB accommodate small packages and fine-pitch components, improving yield and consistency while meeting international production standards.

Quality-control systems, including automated optical inspection (AOI) and reliability testing, help OurPCB verify that each batch of LED PCBs delivers maximum light output with minimal energy consumption. This aligns with evolving market demands for efficient, long-life lighting solutions.

| Trend | Example (2024) | OurPCB Solution |

|---|---|---|

| High thermal materials | Aluminum MCPCB in street lighting | Sourced aluminum-clad boards |

| Thermal simulation | Predictive heat analysis for designs | Custom simulation in prototyping |

| Compact design | Automotive DRL LED modules | Dense yet thermally isolated routing |

| Component miniaturization | SMD LED with 0.2mm pitch chips | Automated fine-pitch assembly |

| Quality-control focus | AOI in production for uniformity | Integrated optical inspection and testing |

About OurPCB

OurPCB is a leading provider of high-quality PCB manufacturing and assembly services.

With a commitment to precision and reliability, OurPCB offers a range of services, including PCB prototyping, mass production, assembly, and testing. Their expertise ensures that clients in industries like electronics, telecommunications, and automotive receive top-tier products and services.

Contact:

Phone: +86-311-85981900

Website: www.ourpcb.com

Frequently Asked Questions

What are the key factors in designing efficient LED PCB boards?

The main factors include balancing heat dissipation, electrical performance, and reliable component assembly. Using high-quality materials, optimizing circuit layout, and ensuring proper thermal management are crucial to maximize LED lifespan and stable light output.

Why is thermal management important in LED PCBs?

Thermal management prevents overheating which can decrease LED brightness and shorten their life. Efficient heat dissipation using heatsinks or metal-core PCBs helps maintain optimal performance and reliability of the LEDs over time.

How does PCB layout affect LED performance?

Good PCB layout improves electrical connectivity, minimizes signal loss and electromagnetic interference, and allows for even power distribution. This leads to consistent performance, reliable operation, and longer product lifespan.

What materials are commonly used in LED PCB boards?

Aluminum core boards are popular for high-brightness applications due to their excellent thermal conductivity. Materials like copper-clad laminates are also used to enhance heat management and support higher current loads.

How can manufacturers reduce costs in LED PCB production?

Minimizing the number of components, optimizing board size, and using automated assembly equipment can lower production costs. Efficient layout and accurate routing also reduce material waste during manufacturing.

What challenges are common in LED PCB design?

Common challenges include signal interference, excessive heat, and maintaining consistent light output. Solutions involve using dedicated ground planes, precise trace routing, and effective thermal management strategies.

What trends are shaping the future of LED PCB design?

Emerging trends include the use of advanced, high thermal conductivity materials, compact board layouts, miniaturized components, and increased automation. Simulation software is also used to predict and improve heat flow and component placement.

How is quality ensured in modern LED PCB manufacturing?

Manufacturers use automated optical inspection (AOI), rigorous reliability tests, and advanced design software to ensure each PCB meets international standards for durability, efficiency, and performance.

Why is uniform light output important in LED applications?

Uniform light output ensures consistent illumination across all LEDs, which is crucial for applications such as automotive lighting and street lamps, where safety and reliability are priorities.

How do LED PCB designs support sustainability?

Efficient LED PCB designs consume less energy, require less maintenance, and have longer lifespans, reducing environmental impact and supporting sustainability in lighting solutions.